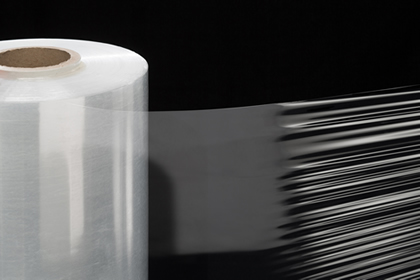

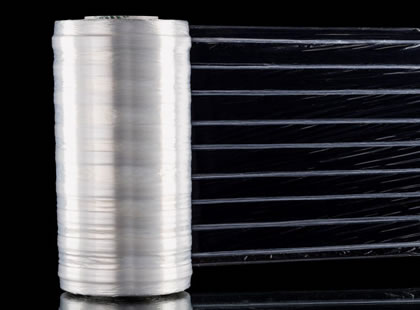

SKIN.LITE Pallet wrap offers several

advantages, such as environmental impact reduction, the decrease in

weight and volume used in each packed product, all this with the guarantee

of maximum resistance and load stability. Although film thickness has

been reduced by up to 65%, the products mechanical performance is maintained

while decreasing the amount of material used. This reduction does not

in any way affect the integrity and stability of the products being

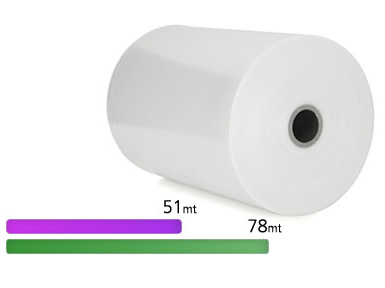

packed. A reduced film thickness and the use of lighter weight cores

allow significantly longer reels. Reduction in roll changing times decreases

downtime and boosts productivity in the packaging process. With its

reduced thickness making warehouse management easier so much that your

storage area can be reduced by up to 65% compared to that required for

thicker products. Lighter Cores mean that although their weight is reduced

by up to 65% compared to standard cores they still provide the same

technical performance in terms of resistance to crushing.

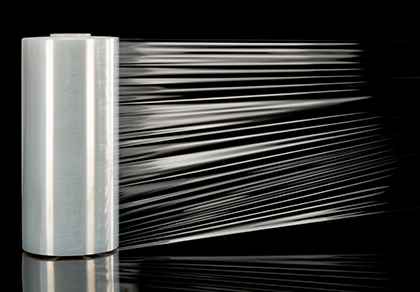

INCREASED STRETCHABILITY

Thanks to its chemical composition,

the new Skin.Lite Stretch Film has very high elongation properties

so that it can be used on all types of machinery and at the same time

allows for using lower amounts of packaging per pallet and optimise

the cost of packaging.As opposed to rigid or pre-stretched films very

thin films between 10 and 6 mu provide up to 50% stretchability further

reducing thickness and ensuring a high clamping force despite their

reduced thickness.

OUR VALUES

- To create products that generate value for their users and to

be an active partner for our customers, even in terms of advice

to protect our customers' assets.

- To offer innovative packaging solutions which can reduce environmental

impact and to provide pre and after sales services.